Dry cargo containers are the most common type of shipping containers used in global trade. They are strong, secure, and designed to transport a wide range of goods, from clothing and electronics to furniture and packaged food. These containers are built to protect cargo from weather, theft, and damage, making them essential for international shipping.

In this article, we will explain the different types of dry cargo containers, their standard sizes, and what they are used for. Whether you are a business owner, freight forwarder, or someone new to shipping, this guide will help you understand how to choose the right container for your cargo.

What are dry cargo containers?

Dry cargo containers are strong, closed metal boxes used to ship goods that don’t need temperature control. They are perfect for dry items like clothes, furniture, electronics, and packaged food. Since they have no cooling or ventilation, they do not typically carry liquids or perishable goods and are best suited for dry, non-perishable cargo that can withstand normal shipping conditions.

These containers protect cargo from rain, dust, and theft, making them the most common type used in shipping. Available in different sizes, they can be easily moved by ships, trucks, and trains, helping businesses send products safely around the world.

Common types of dry cargo containers

Dry cargo containers come in different sizes and designs to accommodate various shipping needs. While all of them are built to be strong, weatherproof, and standardized, their features vary depending on the type of goods they carry. Here are the most common types:

1. Standard dry containers (general-purpose containers)

When people think of a shipping container, they are most likely picturing a standard dry container. These steel boxes form the foundation of global trade, transporting a wide range of non-perishable goods across countries and continents.

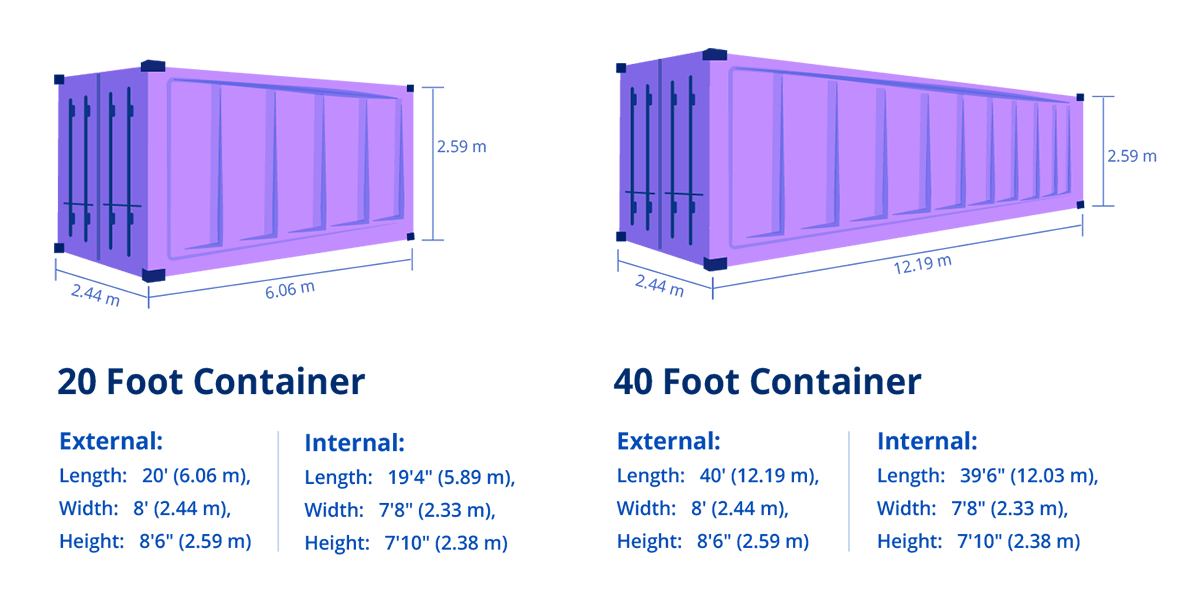

Standard dry containers come in two main sizes:

- 20-foot container (20′ x 8′ x 8’6″) – Ideal for smaller shipments or heavy cargo.

- 40-foot container (40′ x 8′ x 8’6″) – Offers double the space, commonly used for larger shipments.

Image source: Freightos (freightos.com)

Additionally, there’s a taller variation known as the High Cube Container (HC), which is:

- 1 foot taller (9’6″ in height) compared to standard containers.

- Designed for lightweight, voluminous cargo that requires extra vertical space.

- Commonly used for furniture, textiles, oversized equipment, and large industrial components.

Key Features

- Weatherproof & durable – Protects cargo from rain, wind, and harsh environments.

- Secure locking systems – Prevents theft and unauthorized access.

- Standardized dimensions – Easily stacked and transported across ships, trucks, and trains.

- Highly versatile – Suitable for a wide variety of goods, including electronics, textiles, furniture, and raw materials.

Common Industries Using Standard Dry Containers

- Retail & E-commerce – Shipping consumer goods worldwide.

- Relocation – Moving household goods worldwide.

- Manufacturing – Transporting industrial components and finished products.

- Construction – Moving building materials and tools.

- Automotive – Carrying non-specialized parts and accessories.

For businesses new to international shipping, standard dry containers are the go-to choice due to their availability, cost-effectiveness, and adaptability to different cargo types.

2. Double-door containers (tunnel containers)

Double-door containers, often referred to as tunnel containers, are a specialized type of dry freight container featuring doors on both ends. This design enhances accessibility, making loading and unloading quicker and more efficient. Available in 20FT and 40FT standard sizes, as well as high cube variations, they provide greater convenience compared to single-door containers.

Image source: Adaptainer (adaptainer.co.uk)

Key Advantages

- Dual Entry for Efficient Handling – With doors on both ends, cargo can be loaded and unloaded from either side, reducing time and labor. This is particularly beneficial for large, heavy, or irregularly shaped goods that are difficult to maneuver.

- Ideal for Multi-Load Shipments – Businesses can separate different types of cargo within the same container. This means that goods can be accessed from either end, preventing the need to move other items during unloading.

- Versatile Storage & Transport – These containers are widely used for dry, bulk, and special cargo, including vehicles like motorcycles, cars, and snowmobiles. Their flexible entry points make them a practical choice for various industries.

With their sturdy steel construction and high adaptability, double-door containers offer a versatile and efficient solution for transporting, storing, and repurposing cargo.

3. Open top containers

Open top containers are specialized shipping containers without a fixed roof, designed for cargo that requires top loading. Instead of a solid top, they come with a removable tarpaulin or hard cover, allowing for easy access when handling oversized, heavy, or irregularly shaped goods.

Image source: JustContainer (justcontainer.com)

Why Use Open Top Containers?

Unlike standard containers, which are loaded through doors, open top containers allow vertical loading, making them ideal for industries that require quick and efficient transportation of large cargo. They are commonly used in:

- Construction and building materials – Bricks, cement, steel beams, and scaffolding.

- Heavy machinery – Excavators, cranes, and industrial equipment.

- Bulk materials – Grains, ores, and construction aggregates.

- Awkwardly shaped cargo – Goods that don’t fit through standard container doors.

Key Advantages

- Flexible Loading & Unloading: Cranes or forklifts can easily load cargo from above, making handling more efficient.

- Ideal for Tall or Oversized Items: No fixed height restriction, unlike standard dry containers.

- Easy Cargo Inspection: Open top access allows for quick checks before securing the load.

- Durable & Cost-Effective: Made of reinforced steel, these containers provide a long-term shipping solution for heavy loads.

Available in 20FT and 40FT sizes, open top containers are a practical and efficient choice for businesses shipping large or non-standard goods that require a secure yet accessible transport solution.

4. Half-height containers

Half-height containers, also known as Cargo Carrying Units (CCUs), are specialized shipping containers designed for transporting dense, heavy cargo. Unlike standard dry containers, these units are half the height of a typical 20ft or 40ft container, making them ideal for certain industries and specific cargo types.

Image source: TradeCorp (tradecorpshippingcontainers.com)

Why Use Half-Height Containers?

These containers are particularly useful for bulk materials that are heavy but don’t require full container height. Their low profile makes them easier to load, unload, and handle, especially when dealing with:

- Mining materials – Iron ore, coal, mineral salts, and other dense raw materials.

- Construction supplies – Cement, stones, and heavy-duty industrial equipment.

- Offshore and maritime cargo – Pipes, chains, anchors, hooks, and tools used in oil and gas operations.

Key Advantages

- Better weight distribution: Prevents overloading while maximizing cargo space.

- Easy handling: Low height simplifies loading and unloading with cranes or forklifts.

Due to their unique structure, half-height containers are commonly used in mining, offshore, and construction industries where efficient transportation of heavy loads is a priority.

5. Flat rack containers

Flat rack containers are specialized shipping containers designed for oversized, heavy, or irregularly shaped cargo that cannot fit inside standard containers. Unlike traditional containers, flat racks have walls only on the short sides, allowing cargo to extend beyond the container's width or height.

Image source: Seaco (seacoglobal.com)

Key Features & Uses

- Ideal for Out-of-Gauge (OOG) Cargo – Flat racks accommodate large and bulky items such as machinery, vehicles, boats, and construction materials. Their open sides and top make loading and unloading much easier.

- Flexible Loading & Securing – Cargo can be loaded from the top or sides and is secured using lashing straps attached to built-in securing points, similar to how goods are fastened on a flatbed trailer.

- Alternative to Breakbulk or Ro/Ro Shipping – Using a flat rack can be more cost-effective than breakbulk or roll-on/roll-off (Ro/Ro) shipping, as it allows easy integration with container vessels, which have more frequent sailings.

- Standard Sizing Options – Available in 20FT and 40FT sizes, flat racks provide versatile solutions for transporting heavy-duty cargo while maintaining compatibility with shipping networks.

Flat rack containers are essential for industries dealing with oversized equipment, construction materials, and heavy machinery, offering a practical and efficient way to move large goods globally.

Conclusion

Dry cargo containers play a crucial role in global trade by offering a secure and efficient way to transport a wide variety of goods. From standard containers to specialized designs like flat racks and open tops, each type serves a unique purpose, ensuring businesses can move cargo safely and cost-effectively.

Understanding the different container types helps in choosing the right one for your needs, whether you're shipping consumer goods, industrial equipment, or bulk materials. With their durability and versatility, dry cargo containers continue to be the backbone of international shipping, keeping supply chains running smoothly.

Need expert guidance on choosing the right container for your cargo? Connect with our team today and find the best shipping solution for your business!